The Western Treatment Plant uses a low-energy process to treat sewage via a series of large ponds, called lagoons – the largest of which can hold 600 million litres.

As sewage slowly flows through the lagoons, bacteria gradually break down the organic material in the water. The whole process takes about 30 to 35 days to produce Class C recycled water.

With further treatment, the plant can also produce Class A water – the highest standard of recycled water.

It was the first plant in Victoria to do so.

Sewage treatment process

Anaerobic lagoons

The first lagoons have large plastic covers about four times the size of the MCG, which are designed to keep out oxygen. This creates an anaerobic (oxygen-less) environment where certain bacteria thrive.

As the bacteria decompose organic material in the sewage they produce odours and methane gas, also called biogas. This is captured under the covers, reducing odour and greenhouse emissions. The captured gas can then be used on site to power engines that generate electricity.

Did you know the Western Treatment Plant is energy self-sufficient, meeting all its needs through biogas? Learn more about our commitment to improving our energy efficiency.

Aerobic lagoons

Sewage flows into uncovered aerobic ponds, where machines (called aerators) pump oxygen in the water to make it suitable for another type of bacteria. The bacteria remove nitrogen from the wastewater, clumping together in the process.

Once the sewage enters settling tanks, called clarifiers, the solid clumps are easily separated out. The leftover solids are dried and stored in large piles, or reused as biosolids.

Release or recycle

The wastewater has been thoroughly cleaned once it reaches the final lagoon. It can then be released into Port Phillip Bay, under strict conditions set by EPA Victoria to protect the environment, or further disinfected with ultraviolet light and chlorine to produce Class A recycled water.

Each year, the plant produces 40 billion litres of recycled water. This is used to water the plant’s pastures and wetlands, and supplied to customers to water crops, parks and gardens. Some water is further processed to reduce its salt content, before it can be supplied to homes.

Find out why recycled water is so important to Melbourne, with population growth and climate change creating a 'new normal' for our water storage levels.

You may also like...

Follow our online community hub and be the first to know about new projects, ways to visit and opportunities to help shape the future of the site.

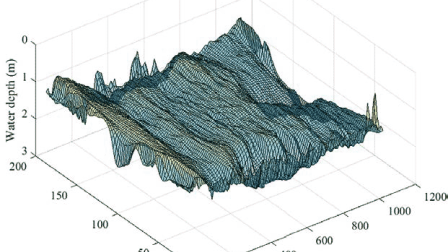

Autonomous remote-operated vehicle technology for desludging lagoons

Case study: Underwater drones are reducing the effort and cost of mapping sludge build-up in wastewater treatment lagoons.

Shortcut nitrogen removal plant reducing emissions

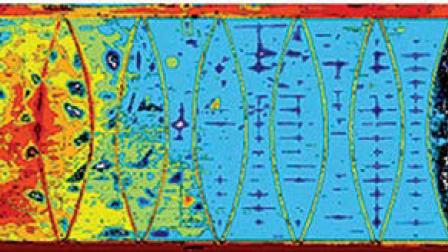

Case study: a two-and-a-half year trial of shortcut nitrogen removal has shown potential to transform the way we treat wastewater, while saving costs.

Photogrammetry detecting changes in polymer covers

Case study: we've used photogrammetry to develop a safer way to inspect floating covers over the lagoons at the Western Treatment Plant.

Bird species at the Western Treatment Plant

Tens of thousands of birds flock to the Western Treatment Plant, with nearly 300 species recorded at the site.