A virtual reality ozone generator developed for training has familiarised our staff with new technology they need to maintain, improving safety and confidence. Read this case study to learn more.

Sustainable Development Goals:

Goal 3: Good health and well-being

Goal 9: Industry, innovation and infrastructure

Background

An astonishing 350 million litres of sewage is treated each day at our Eastern Treatment Plant.

To produce the highest quality recycled water, our treatment process includes state-of-the-art ozone treatment. Ozone is a highly reactive form of oxygen, which cleans wastewater by stripping the electrons off organic matter. Because of its reactivity and the large quantities we need to treat such high volumes of water, we generate this ozone onsite.

Like any machinery, ozone generators sometimes need to be isolated for maintenance or repairs. This process is one of our riskier ones, involving more than 40 steps. Operator familiarity with the equipment is important to maintain safety and develop confidence, but training cannot be done routinely.

Research focus

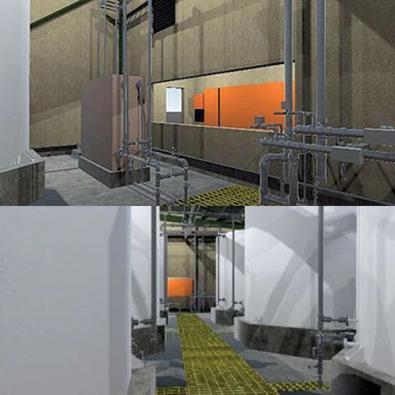

Our Safety team created a virtual reality ozone generator to address this issue. The generator uses hand-tracking technology enabling users to interact with the virtual menu and ‘walk’ through the plant, finding and fixing potential hazards and operating and locking isolation valves as needed.

The software also allows multiple users to interact in the same virtual reality environment, irrespective of where they are located. This means we can access experienced technical support from anywhere in the world to support our operators.

Outcomes

The virtual reality ozone generator is an extension of Melbourne Water’s virtual reality program, which builds replicas of new equipment to help familiarise our staff with new technology before they are called on to maintain it.

Virtual reality to review engineering design

When designing a new facility and the associated treatment equipment, a final step in the process is a workshop to review the drawings by those who will use the equipment or facility. This review was previously based on 2D paper or screen-based drawings. But these have now been replaced with virtual reality technology that enables a virtual tour of the planned facility.

This is now a mandatory process for all of Melbourne Water’s major projects and the feedback has been extremely positive. By embarking on one of these virtual reality review tours, a technician can now simulate completing a task in the virtual world and explain to the designers whether or not there are access or design issues in the plant.

On average this approach has identified four times more design issues than the traditional workshops, and takes a quarter of the time to complete.

You may also like...

Delivering on the Sustainable Development Goals

This report outlines Melbourne Water's unwavering commitment to advancing sustainability through the United Nations Sustainable Development Goals (SDGs).