Melbourne Water and Monash University have used photogrammetry to develop a safer way to inspect floating covers over the lagoons at the Western Treatment Plant, enabling more accurate maintenance scheduling and safe operation for the longest possible period. Read this case study to learn more.

Sustainable Development Goals:

Goal 6: Clean water and sanitation

Goal 7: Affordable and clean energy

Goal 11: Sustainable cities and communities

Goal 13: Climate action

Background

Photogrammetry is the science of making measurements from photographs. These are often 2D aerial photographs, which can be used with computers to calculate actual measurements – and even to determine measurements in 3D. A 3D image generated from this process can then be 3D printed, and the printouts used as models when sharing ideas for proposed or new works with stakeholders and the community.

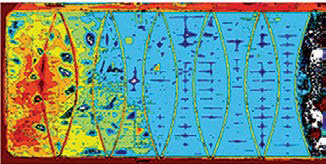

With this process in mind, we wanted to know if 2D aerial photographs of the floating polymer covers at the Western Treatment Plant could be used to generate a 3D shape for identifying distress ‘hot spots’ in the covers.

These 10-hectare covers collect biogas from the anaerobic digestion of wastewater. This biogas is then used to produce renewable electricity, providing almost 100 per cent of the energy requirements of the entire treatment plant.

Research focus

Currently, field personnel at the plant need to walk over the covers to detect defects or take measurements to determine the amount of solid scum underneath them. Scum moves slowly under the covers and tear them, making inspection risky.

Working with Monash University, we have been using photogrammetry to develop a safer inspection method that will enable more accurate maintenance scheduling and ensure the covers operate safely for the longest possible period.

Outcomes

Of immediate and additional benefit to operators is that photogrammetry can be used to identify and quantify the volume of scum and biogas between the underside of the covers and the surface of the lagoons, and how and where this changes with time.

By applying ‘filters’ to the collected data, we can also monitor the occurrence of wrinkles and arrange for timely and relevant action. The results are showing that photogrammetry offers a viable alternative technique for the monitoring and assessment of the floating covers. We are continuing to work to automate as much of the process as is practicable.

You may also like...

Delivering on the Sustainable Development Goals

This report outlines Melbourne Water's unwavering commitment to advancing sustainability through the United Nations Sustainable Development Goals (SDGs).

Our Path to Net Zero

We’re taking action on climate change to protect the natural resources that sustain us so Melbourne remains a great place to live.