In Melbourne, a safe, clean and healthy environment is essential to our way of life.Through an extensive network of underground pipes, sewers and treatment plants we manage and treat our city’s sewage, ensuring the health of our environment, our communities and our families.

Our city is always changing with more and more people wanting to call Melbourne home. Without innovations and improvements our sewerage network could reach capacity and our waste may impact on the health of our environment and communities.

One of these impacts can be odour. Although the incidence of odour complaints from our operations have declined significantly over time, we acknowledge that Melbourne Water operations, including our sewage treatment plants, may cause odour from time to time.

That’s why we have an extensive odour monitoring program and why we are always looking for new ways to avoid and minimise this impact in our operations and projects where practical. We aim to ensure our local community is not regularly affected by odour and have a range of measures in place to do this.

What causes odour from our treatment plants?

Eastern Treatment Plant (ETP)

Sewage entering the plant goes through an intensive three-stage treatment process, which only takes 24 hours. This process includes advanced tertiary treatment including ozone and biofiltration which produces a very high treated water quality with no residual odour. This process meets the requirements for both safe discharge to the marine environment at Boags Rocks on the southern Mornington Peninsula and Class A recycled water.

The residual solids from sewage treatment is treated using anaerobic digestion to produce biogas, which is used to generate renewable electricity meeting 30% of plant’s needs.

As part of this process, the Eastern Treatment Plant (ETP) has large open lagoons, referred to as Sludge Drying Pans, to dewater (drain) and dry the remaining solids product from the sewage treatment process. The Sludge Drying Pans and associated treatment systems can be odorous, and can cause odour at and beyond the plant boundary under certain wind and atmospheric conditions, resulting in poor odour dispersion. Odour can also occur when vegetation in sometimes empty lagoons is flooded during wet conditions and the vegetation rots.

The ETP site is much smaller than the WesternTreatment Plant (WTP) and has significantly less buffer distance between odour sources and the plant boundary. To control and mitigate offensive odour at and beyond the plant boundary, where possible the unpleasant odour from ETP sources is collected and treated. The remaining odour sources are generally very large and open, such as the Sludge Drying Pans and lagoons, which cannot be covered. On any given day, there are multiple projects underway at the ETP to improve the way we treat and manage your sewage. As we continue to work on exciting new projects, you may experience odour from the ETP from time to time, and we know this can be unpleasant. We aim to ensure our local community is not regularly affected by odour and have a range of measures on place to do this.

Western Treatment Plant (WTP)

The WTP primarily uses a low-energy process to treat sewage via a series of large ponds, called lagoons – the largest of which can hold 600 million litres. The WTP process is gradually becoming more mechanised to accommodate an increase in sewage as a results of a growing Melbourne, as well as manage and reduce environmental impacts.

As sewage slowly flows through the lagoons, bacteria gradually break down the organic material in the water. The whole process takes about 30 to 35 days to produce Class C recycled water. With further treatment, the plant can also produce Class A water – the highest standard of recycled water. It was the first plant in Victoria to do so.

Foul air from the incoming sewer at WTP is collected and treated in the Odour Control Facility (OCF). The WTP also utilises its significant land size as a buffer between other plant odour sources and the plant boundary.

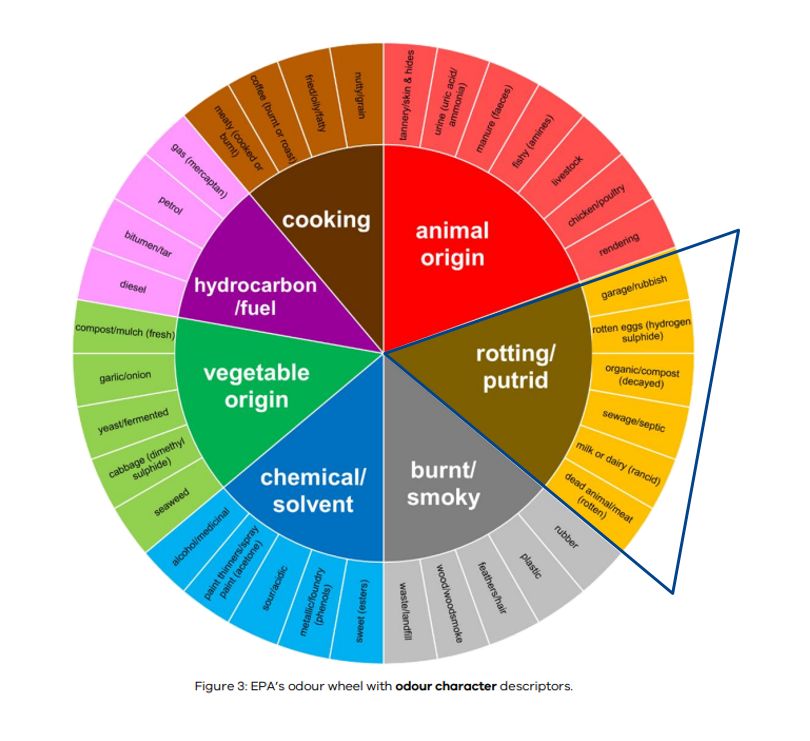

Odour coming from our sites is likely to fall under the rotting/putrid section of the EPA odour wheel.

How to report odour

We want to make it easy for you to get in touch with us.

If you experience odour that you suspect is coming from a Melbourne Water asset or location, please report it directly to us by calling 13 17 22.

Providing details such as when you smelt the odour, what it smelt like and how long you smelt it for will help us to investigate the odour in a timely way.

EPA’s odour list helps you identify an odour – for example, odour from animals, chemicals, burning or cooking.

- When you report odour that you think is coming from Melbourne Water sites, you can use the EPA’s odour list to describe it.

- In general, we know that odour from Melbourne Water’s sewage treatment sites will often have a rotting/putrid smell due to the presence of hydrogen sulphide and similar odorous compounds. See Appendix 1 for EPA’s odour wheel

- If Melbourne Water operations are confirmed as the odour source of your odour complaint, we will let you know and work to address any issues at the location that may be causing this.

- If you would like to report an odour that you believe is coming from one of our sites, please call us to report this at the time of smelling the odour so we can investigate it in a timely way. Please do not log odour reports online, as there may be a delay in Melbourne Water staff investigating the odour report.

- We’ll also notify our environmental regulator, EPA Victoria, of any confirmed odour complaints.

Response timeframes

We aim to get back to you within the following timeframes:

| Enquiry type | Response time |

| Phone | 1 business day. |

| Complaints |

10 business days. We will acknowledge your complaints within one business day and aim to resolve your complaint within 10 business days. If it takes longer, we’ll update you on our progress. |